Wudi Hizen takes quality control seriously. For each specific application, we use only the most befitting materials produced by the most reliable suppliers. As soon as the materials arrive at our factory, we conduct vigorous tests to ensure they are up to standard.

Wudi Hizen’s flexible pipeline production Plant has a dedicated quality department for raw material inspection, process inspection and factory acceptance testing.There are 18 personnel in total including two managers, two quality engineers, and 14 technicians. The Inspectors (including MT and PT inspectors) have got class I and II class II qualifications.

Material inspection

Wudi Hizen has inspection and testing capabilities in the fields of mechanics of materials, physical chemistry, geometrical quantity and pyrology with many special discipline labs for mechanics performance testing, fatigue testing, precise instrument, creep testing, aging testing and stress corrosion testing, etc. Wudi Hizen has invested with more than 160 sets of testing equipment and could provide testing service conforming to API 17J requirements.

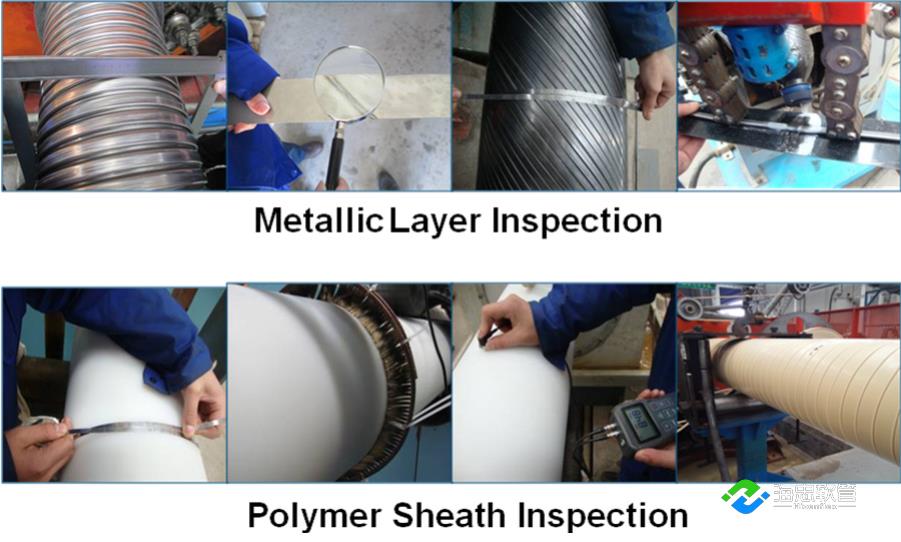

Process inspection

The cladding production line has been equipped with high-end online thickness gauges which can measure wall thicknesses ranging from 2mm to 20mm with laser and ultrasound. It monitors non-stop the pipe thickness to ensure the quality of our products.

All the metal welding during process will be tested by NDT. And NOED has also equipped all kinds of measuring instruments, such as online leak detectors, handheld thickness gauges, venire calipers and steel rulers, etc. Our equipment measures the steps and outer diameters of each specific layer in real time while the steel tapes are being wounded onto the pipe. Therefore, the process inspections are in full compliance with API 17J.

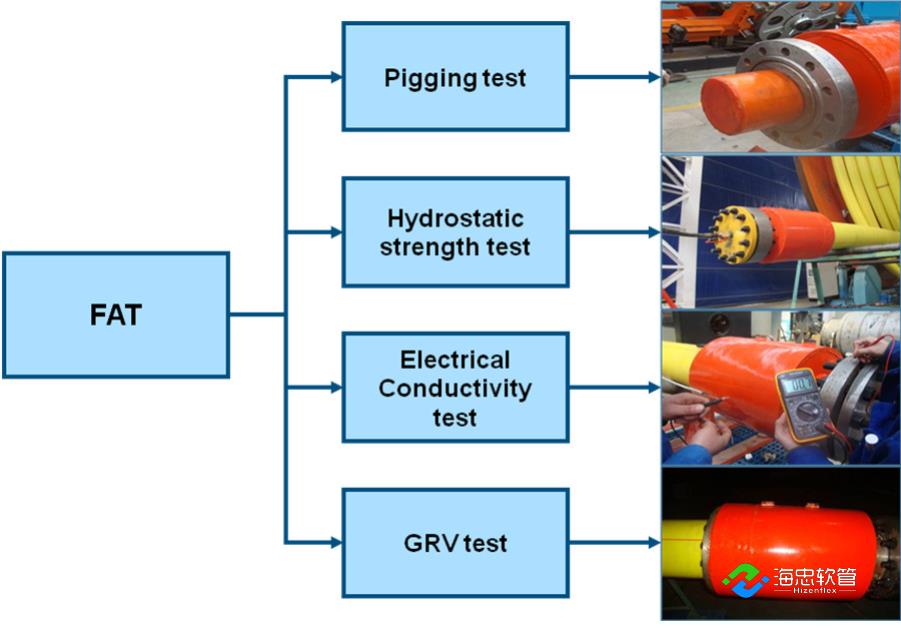

PROTOTYPE TEST AND FACTORY ACCEPTANCE TEST

Wudi Hizen has professional personnel and equipment for the prototype test and FATs outlined in API 17J. We test our products with regards to their geometry, static pressure capacity, electrical resistance, and the functionality of the venting valves. All the aforementioned inspection and testing are witnessed by third party certification bodies (i.e. BV).