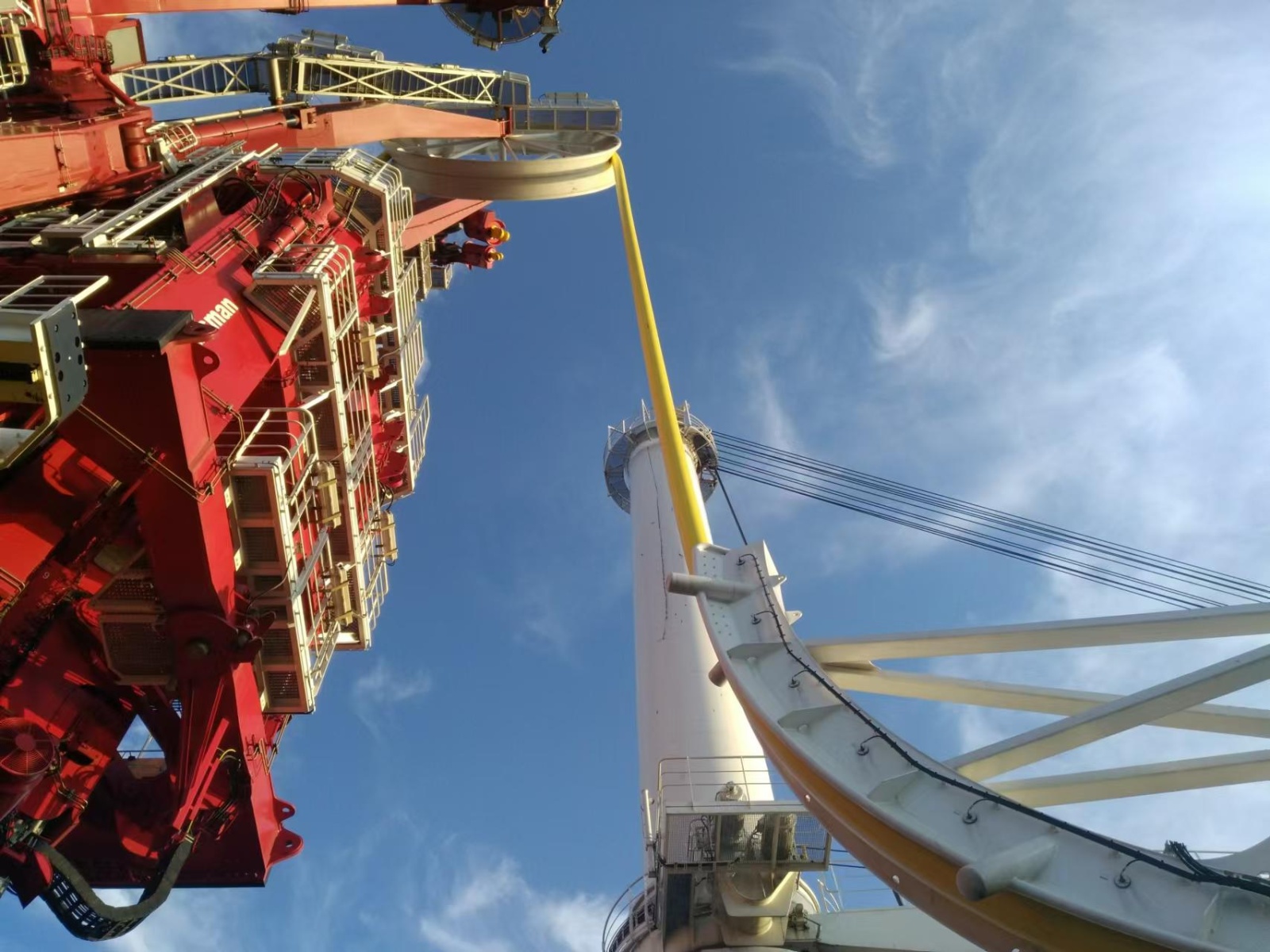

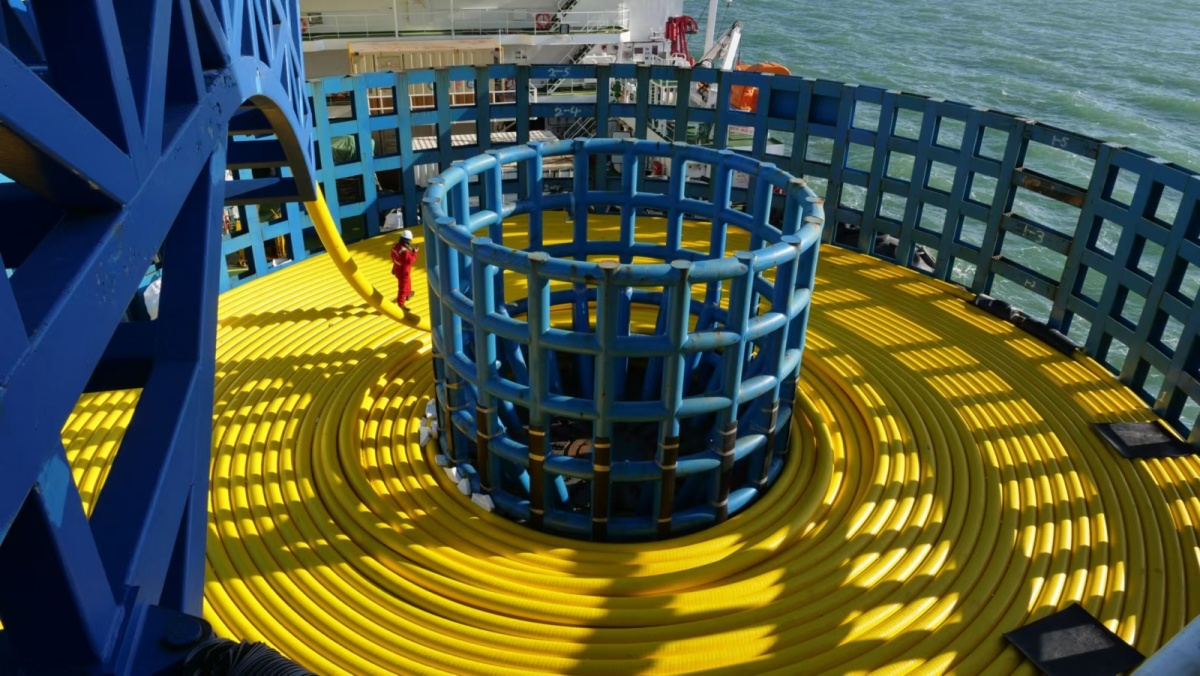

Compared with steel pipe, non-bonded flexible composite pipe has better compliance and continuity, is resistant to high temperature, high pressure, and strong corrosion, and can be used in ultra-deep-sea resource development above 6000m, which plays a critical role in marine oil and gas resource development.

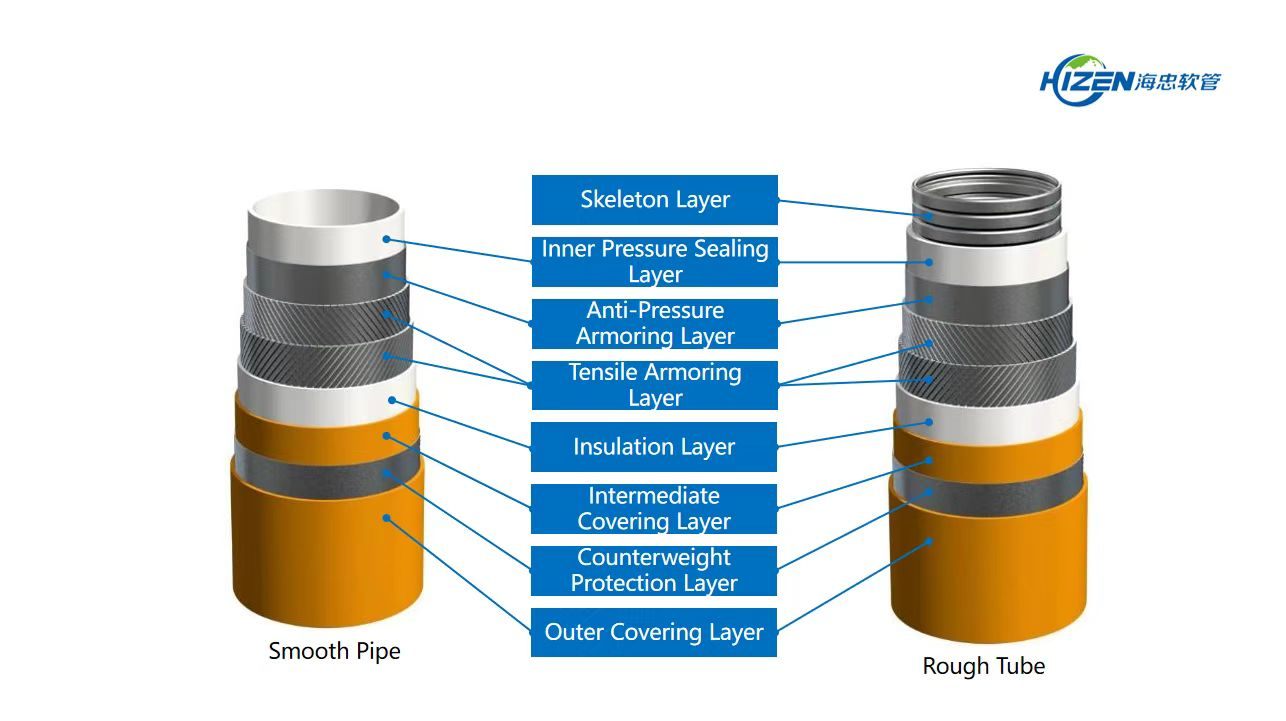

The typical construction of non-adhesive flexible composite pipe mainly includes: the skeleton layer, inner lining layer, anti-pressure armoring layer, wear-resistant layer, tensile armoring layer, intermediate layer (multi-layer/multi-structure, optional), and outer covering layer. Each layer has different roles in the pipe and can be designed according to the actual requirements, and each layer structure requires different forming and manufacturing equipment and processes for production.

The application of marine pipe engineering integrates material science, structural mechanics, thermodynamics mechanical manufacturing, and other multidisciplinary disciplines, develops the theory of cross-section design, and optimizes the processing and manufacturing technology to provide a reliable guarantee for achieving independent innovation and localization.